1. Ke engEVA Hot Melt Adhesive Film?

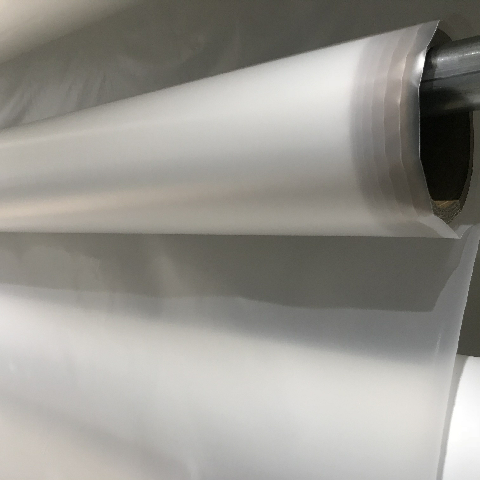

Ke sekhomaretsi se tiileng, sa thermoplastic se fanoang ka filimi e tšesaane kapa sebopeho sa webo.

Motheo oa eona oa mantlha oa polymer keEthylene Vinyl Acetate (EVA)copolymer, eo hangata e kopantsoeng le li-resin tse tackifyng, boka, li-stabilizers le li-modifiers tse ling.

E sebelisoa ke mocheso le khatello, e qhibiliha ho etsa sekhomaretsi se matla ha se pholiso.

2. Lintho tsa Bohlokoa:

Thermoplastic:E qhibiliha ha e futhumala 'me ea tiea ha e tsidifala.

Ha e na Solvent & Eco-Friendly:Ha e na li-volatile organic compounds (VOCs), e etsang hore e hloeke hape e sireletsehe ho feta likhomaretsi tse thehiloeng ho solvent.

Fast Bonding:Ts'ebetso le maqhama li etsahala kapele hang ha mocheso le khatello li sebelisoa.

Mokhoa o motle oa ho qala:E fana ka ts'ebetso e matla ea pele ha e qhibiliha.

Ho feto-fetoha ha maemo:Lifilimi tse thehiloeng ho EVA ka kakaretso li boloka ho feto-fetoha ha maemo ka mor'a ho tlamahanngoa, ho lumellana hantle le li-substrates.

Wide Adhesion Range:Li tlamahane hantle ho lisebelisoa tse fapaneng tsa porous le tse se nang porous (masela, foam, polasetiki, lehong, tšepe).

Ho sebetsa ha bonolo:E lumellana le lisebelisoa tse tloaelehileng tsa lamination tsa indasteri le lisebelisoa tsa bonding.

Litšenyehelo:Ka kakaretso tharollo ea sekhomaretsi e theko e tlase ha e bapisoa le mefuta e meng ea HMAM (joalo ka PA, TPU).

3. Lisebelisoa tsa mantlha:

Lesela le Liaparo:

Laminating masela (mohlala, interlinings bakeng sa melala, cuffs, waistbands).

Hemming le ho tiisa seam.

Ho kopanya li-appliqués, li-patches le lileibole.

Ho kopanya masela a sa lohiloeng (mohlala, lihlahisoa tsa bohloeki, li-filters).

Likarolo tsa lieta tse tlamang joalo ka li-puffs tsa menoana, li-counters, insoles le linings.

Ho hokela holimo ho li-midsoles kapa li-outsoles (hangata li kopantsoe le likhomaretsi tse ling).

Laminating letlalo la maiketsetso le masela.

Sephutheloana:

Lamination e khethehileng ea ho paka (mohlala, pampiri / foil, pampiri / polasetiki).

Ho tiisa mabokose le mabokose.

Ho etsa mabokose a thata.

Likoloi le Lipalangoang:

Ho kopanya likarolo tsa ka hare tsa trim (li-headliner, liphanele tsa mamati, lik'hapete, li-trunk liners).

Laminating masela ho foams kapa composite.

Ho tlama ka bohale le ho tiisa.

Thepa le Upholstery:

Ho kopanya lesela ho foam padding.

Ho tiisa le ho lamination ka materase le li-cushions.

Laminating mekhabiso holim'a metsi.

Lisebelisoa tsa Tekheniki le Laminate tsa Indasteri:

Likarolo tse kopanyang mecheng ea litaba tsa ho sefa.

Laminating geotextiles.

Ho theha lisebelisoa tse kopaneng bakeng sa ts'ebeliso e fapaneng ea indasteri.

DIY & Crafts:(Mefuta e ka tlase ea melt point)

Lisebelisoa tsa ho kopanya bakeng sa merero ea ho itlosa bolutu.

Mesebetsi ea matsoho ea masela le mekhabiso.

4.Ho sebetsaMekhoa:

5.Flatbed Lamination:Ho sebelisa mechine e futhumatsang ea platen.

Continuous Roll Lamination:Ho sebelisa lirolara tse futhumetseng tsa almanaka kapa li-nip rollers.

Contour Bonding:Ho sebelisa lisebelisoa tse futhumatsang tse khethehileng bakeng sa libopeho tse khethehileng.

Ts'ebetso ea Ultrasonic:Ho sebelisa matla a ultrasonic ho qhibilihisa filimi sebakeng sa heno (e sa tloaelehang haholo bakeng sa EVA ho feta mefuta e meng).

Tshebetso:Beha filimi pakeng tsa li-substrates -> Etsa kopo ea mocheso (ho qhibiliha filimi) -> Sebelisa khatello (ho netefatsa ho kopana le ho kolobisa) -> Ho pholile (ho tiisa le ho theha maqhama).

6. Melemo ea EVA HMAM:

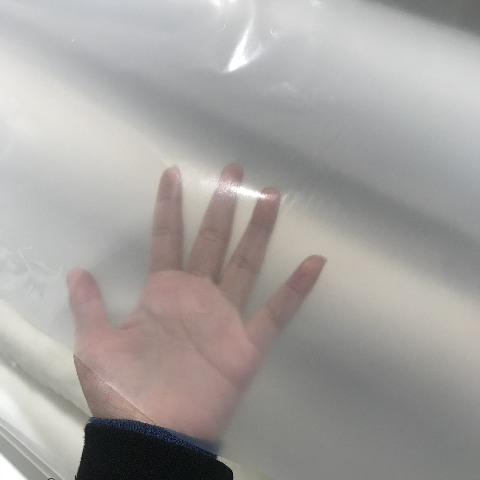

E hloekile ebile e bonolo ho sebetsana le eona (ha e na litšila, ha e na lerōle).

Botenya bo tsitsitseng le kabo ea sekhomaretsi.

Ha ho nako ea ho omisa / ho folisa e hlokahalang ka mor'a ho tlamahanngoa.

E babatsehang ho boloka botsitso tlas'a maemo a tloaelehileng.

Ho leka-lekana hantle ho khomarela, ho tenyetseha, le litšenyehelo.

Lithempereichara tse tlase haholo ha li bapisoa le tse ling tsa HMAM.

6. Meeli/Maikutlo:

Sensitivity ea Mocheso:Litlamo li ka nolofatsa kapa tsa hlōleha ho mocheso o phahameng (hangata o lekanyelitsoe ho <~ 65-80 ° C / 150-175 ° F ts'ebeliso e tsoelang pele, ho itšetlehile ka ho etsoa).

Ho hanyetsa Lik'hemik'hale:Ka kakaretso ha e khone ho hanyetsa lihlapolli, oli le lik'hemik'hale tse matla.

Creep:Tlas'a mojaro o sa khaotseng, haholo-holo ka mocheso o phahameng, likarolo tse tlanngoeng li ka 'na tsa thella (butle-butle li senyeha).

Ho hanyetsa Mongobo:Ts'ebetso e ka fetoha ho latela sebopeho; ha e na metsi ka tlhaho joalo ka lifilimi tse ling tsa PUR.

Tšebelisano ea Substrate:Le hoja e le bophara, ho khomarela lipolasetiki tsa matla a tlaase haholo (joaloka PP, PE) hangata ho hloka phekolo ea holim'a metsi kapa mekhoa e itseng.

Qetello:

Filimi ea EVA Hot Melt Adhesive ke tharollo e sebetsang ka mokhoa o fapaneng, e theko e tlaase, ebile e bonolo ho e sebelisa, e sebelisoang haholo ho masela, lieta, liphutheloana, ka hare ho likoloi, thepa ea ka tlung le masela a indasteri. Matla a eona a bohlokoa a holim'a boiketlo ba eona ba ho sebetsa, ho tenyetseha hantle, mokhoa o matla oa pele, le tlhaho e se nang solvent. Le hoja mocheso oa eona le khanyetso ea lik'hemik'hale li beha mefokolo e itseng, e ntse e le khetho e ka sehloohong bakeng sa lits'ebetso moo lintlha tsena li seng mahlonoko le ho boloka litšenyehelo ho bohlokoa.

Nako ea poso: May-29-2025